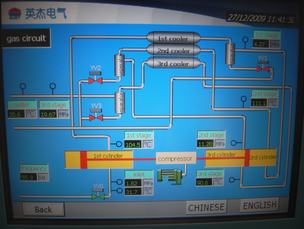

Compressor PLC control panel

Advantages:

1. Each compressor is equipped with separated PLC control panel and 7-10 inch touchable screen.

2.The compressor has a great function of protection and autocontrol by adopting PLC programmable controller, which is featured by advanced skill, reliable quality, high safety degree and high automation. It has also realized automatically opening, stopping, loading and discharging and the function of hand motion. The key parts of the controlling device utilize programmable controller, text display (TD-200) and AC electromagnetic contactorof international brand S7-200 (SIEMENS).

3. The pressure and temperature of the compressor can be displayed and alarmed by the machine. Besides, it adopts the programmable controller (Siemens S7-200 in German) that has 24 types of input switches, 12 types of imitated outputs and 16 types of output switches; text display includes English operation system, that is monitoring and operating each states through the operation push-button on operation system (including transmitter, solenoid valve and controlling board).

4. The skill and assignment of PLC controlling is advanced.

Systems are as follows:

1. PLC controlling cabinet consists of major loop and controlled returning circuit, while the major loop consists of plastic-covered circuit breaker, contactor and soft starter. And the controlled returning circuit is composed of PLC(CPU224, A/D mold, TD200 display, electric resource switch, central relay, push-button, directional lights, voltage meter and current meter.

2. It has the cut-off function of faults alarm.

3. It can start both working modes, hand-operation and auto-operation

4. The main method of starting the main machine is soft starting, and the main motor will be delayed after starting the oil injected pump.

5. Automatic mode: it can automatically control the starting, loading, circulating and stopping of the compressor to achieve

auto-protection. PLC board can also diagnosis faults — the setting of the controlling machines and the displaying of circulating parameter.

Protection Object

1. Over/lower-pressure protection for inlet pressure of the compressor

2. Over- pressure protection for every stage discharge pressure

3. Over -temperature protection for last stage outlet of temperature

4. Lower-pressure protection for lubricating oil pressure

5. Over-pressure protection for cooling water pressure

6. Over-load protection for the motor /generator of compressor

Push Button FOR

1. Restart of compressor after emergency shut-down

2. Emergency shut-down

3. Starter: soft starter

4. Option for inverter starter