LCNG-LNG Fueling Station

Features:

1. Skid-mounted LNG/LCNG/CNG combination filling station

2. Skid-mounted LNG/LCNG/CNG combination filling station, which is adaptability, can refuel cars .by LNG in different phase state .

Technical Features:

1. LNG vaporization zero-loss.

2. Equipment configuration flexibility. Customers can either choose the LNG/LCNG/CNG combination filling station or dividedly use LNG filling station, LCNG filling station and CNG filling station.

3. Convenient operation and maintenance. LNG filling station adopting PLC control, can achieve automatic control over the LNG storage tank, automatic control over the LNG filling pressure and automatic metering and billing of natural gas in the filling time.

4. A high degree of integration. Achieved complete skid-mounted already, the equipment can start production simply after connecting power supply, and it can be moved or relocated conveniently, maximum for the user to save installation time and costs and to make the user’s benefits maximizing.

5. Safe. Doing the research of safety and operability through the whole process removes the various kinds of potential risks during the period of design and manufacturing.

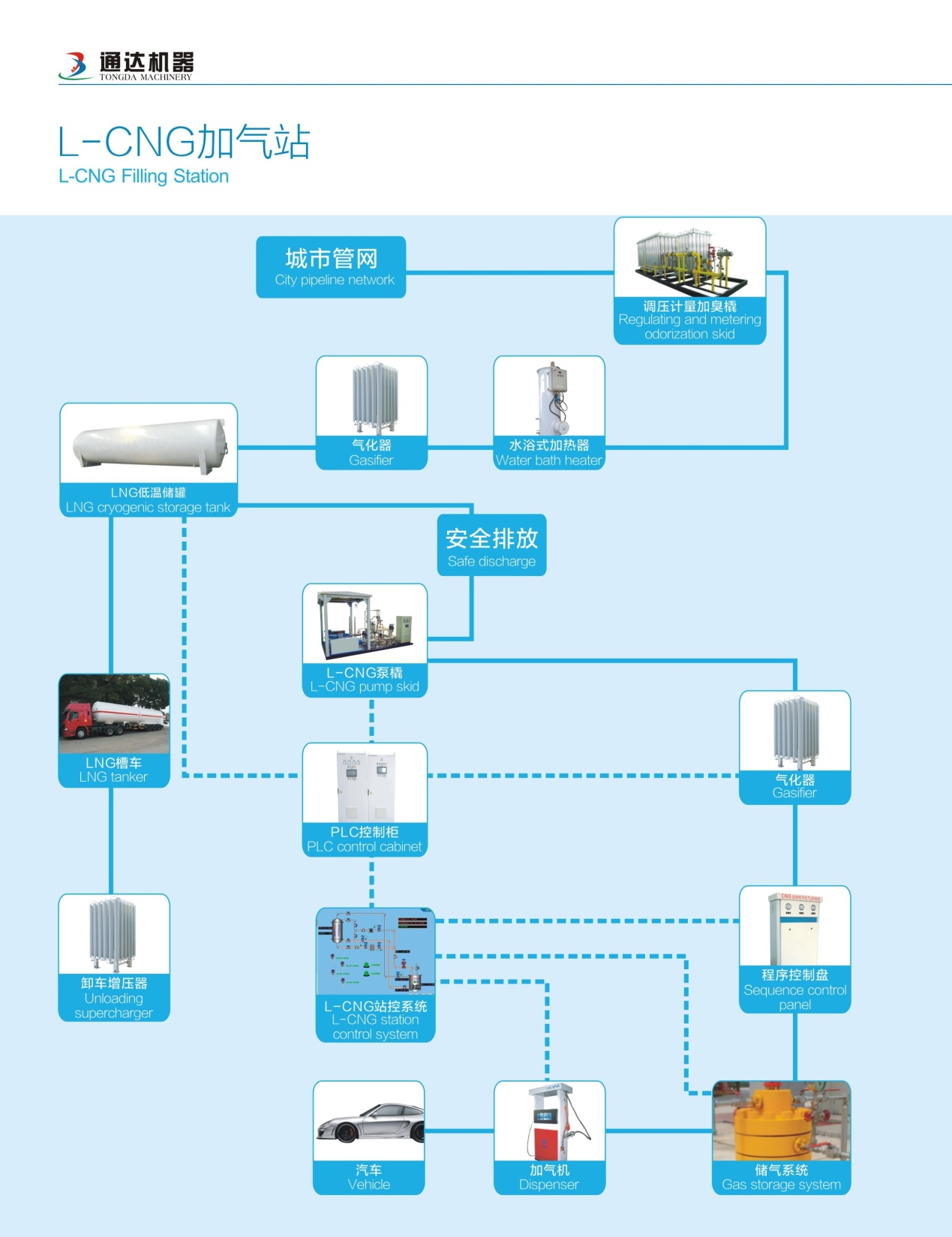

LCNG Filling station flowchart

LCNG Filling Station

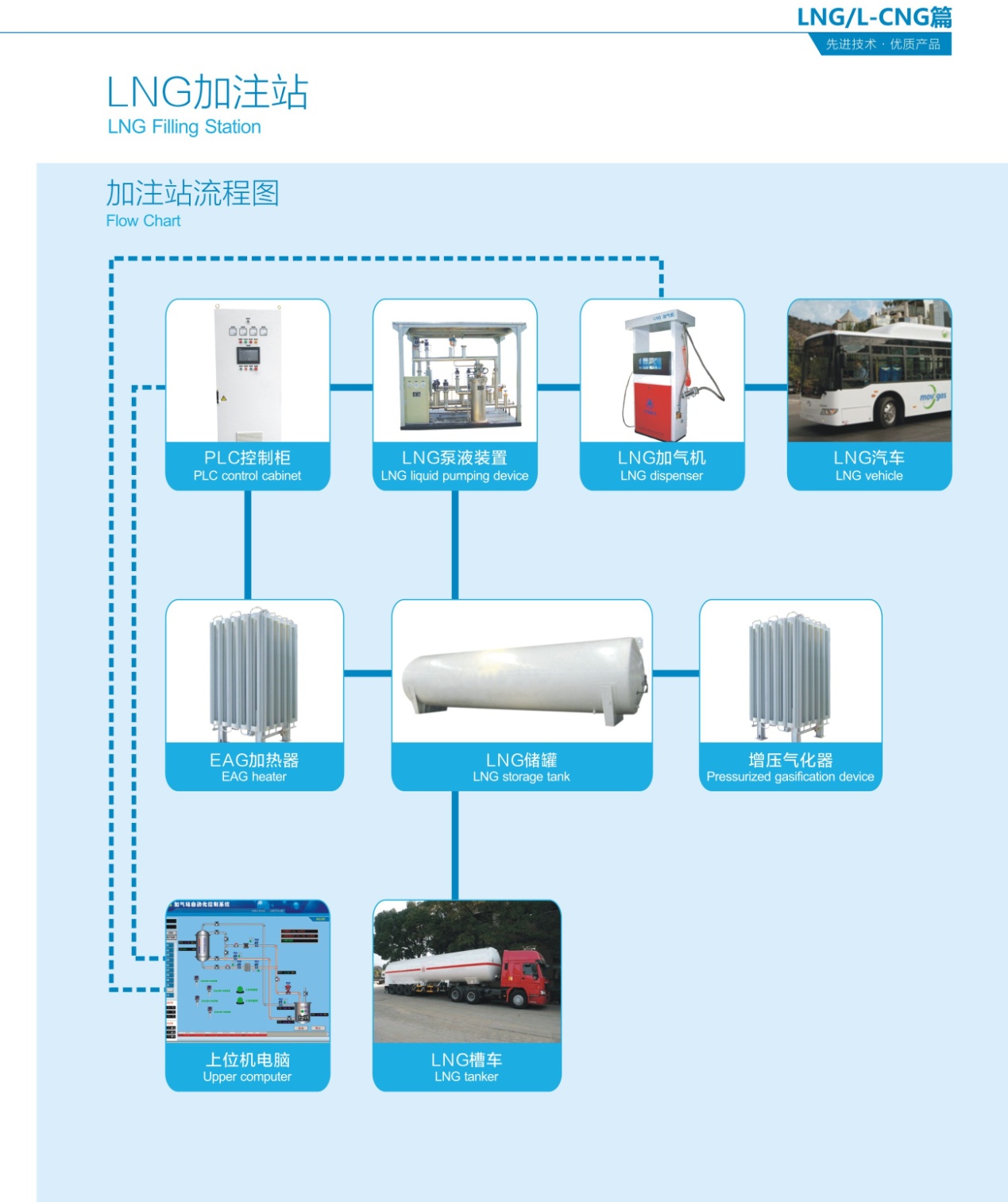

LNG Refueling Stations Flow Chart

LNG Refueling Stations

Specifications

1. Parameter Name Parameter Value range Notes

2. Filling capacity (Equivalent to the standard gas) Nm3/d 5,000~20,000 (determined by the user’s needs)

3. Vehicles can be refueled per day 20~100 (determined by the tank capacity)

4. Filling time: min/cars 3~6 (determined by the tank capacity)

5. Measurement accuracy 1.0%

- Offshore Platform Gas CompressorsOffshore drilling platform compressors are applied to the pressure boostingtransportation and shaft bottom back pressure of natural gas in the offshore drilling platform. Nowadays, tens of compressors, acted as ...

- Biogas Plant Gas CompressorsWe mainly supply all kinds of compressors for biogas plant to supercharge gas in the process of methane gas handling, and to operate synchronously with all the central control equipments.1. High automation 2. Low intake pressure designing ...